Recirculation mills make use of water wheels and pumps or related devices.

As the historical section of this chapter grew beyond manageability, I decided

to move parts of this chapter into the history section. There you will find

all information you need to know if PMMs based on water machines are discussed.

But do not forget to return to this chapter!

If you want to learn more about recirculation mills without reading the facts

about their mechanical basics check these chapters:

In classical machine construction, water wheels are characterized by a horizontal

axis. We basically can distinguish 3 types of water wheels.

|

The undershot water wheel

This type is the oldest. Vitruv described that type of water wheel in the

1st century B.C. It can be used wherever a swiftly running river is available.

Its efficiency is around 25% In the 19th century, this type of wheel was

further develeped. Especially the design by Poncelet reached and efficiency

of 70%. |

|

The overshot water wheel

Overshot water wheels are in use since the 14th century. If they are well-made

and the height of the upper water reservoir allows a large diameter of the

wheel, an efficiency up to 75% or sometimes even 80% is possible. |

|

The center water wheel

This is the most recent type, being developed in the 16th century. It is

a compromise between the two basic constructions. Older versions had up to

45% efficiency, modern types can reach up to 75% efficiency. |

The typical construction element of water turbines is a vertical axis. The

first wheels of this kind were invented and depicted in the late sixteenth

century. Due to the shape of the shovels, they sometimes are called spoon

wheels. The development of the modern water turbines began around 1820.

1824, the expression turbine was coined by the french engineer Claude

Bourdin.

|

This type of water wheel with vertical axis dates back to the end

of the sixteenth century. The earliest design I could figure out is this

one by Giovanni Branca. The construction element was used by Jacopo Strada

for a recirculation mill which thus became the first PMM with a water turbine.

Later, Andreas Boeckler recycled the idea in the mid-seventeenth century. |

|

In places were swiftly running water is abundant, even primitive turbines

survived until the twentieth century like these in the austrian Alps. Their

efficiency is bad, but sufficient enough for the purpose, which in this case

is grinding of marbles. |

|

Modern turbines, like this disassembled Francis turbine (around 1880)

have high efficiency of 80%, sometimes up to 90%. |

Other Water engines

yyy

Systematic Research on Water

Engines

In the second half of the 18th century, first systematic research was made

to learn how water wheels worked and how to improve their efficiency by a

suitable design. The epoch is characteristic for the beginning of the industrial

revolution. We have to keep in mind, that James Watt also made his reasearch

work on steam engines at that time.

The task to improve water wheels was not only caused by scientific interest;

but rather a commercial issue which made good energy sources crucial for

a flourishing manufacturing industry.

|

|

Piston pumps are a roman invention. They date back to 250BC. Authors

like Vitruv and Heron of Alexandria give descriptions of pumps and other

mechanisms whose function is based on cylinders and pistons. |

|

|

Classic sucktion pumps only work, if water is to be pumped up less than

approx. 10m (=33ft). In ancient times, this effect was explained by Aristotle's

horror vacui i.e. nature abhors vacuum. It took until the

mid-seventeenth century until Evangelista Torricelli, a pupil of Galileo

Galilei found the correct explanation. |

The Archimedian Screw

The Archimedian screw is a very old type of pump. Researchers today think

that the name is appropriate, as it can be tracked back until around 250BC.

It was known in ancient greece and rome and even today has great practical

value although most people are not aware of it, as the principle often is

concealed in machine housings. Archimedian screws are used to lift water

for irrigation purposes. As the device works continously, it can be operated

in an easier manner than an piston pump with its intermittent working cycle.

In ancient times, turning pumps used to be slaves' labour. Until recent,

archimedian screws were in use in the middle east.

|

|

|

| A cross-section through an Archimedian screw |

|

Irrigation in Egypt around 1950 |

|

|

The principle of the Archimedian screw can also be utilized to win mechanical

energy. Often, the idea is attributed to Giovanni Branca, who described 1629

a predecessor of today's water turbines. In fact, Leonardo da Vinci made

the same suggestion already around 1490. He used the principle for a

perpetual motion machine! |

Other Types of Pumps

yyy

The hydraulic ram is a remarkable machine, as it can lift water higher than

the running water flow which is used to power the machine. This sounds paradox

at the first glance and seems to open a loophole for recirculation mill

construction, but the first law of thermodynamics demands its tribute. The

hydraulic ram was invented by Etienne Mongolfier, who was one of the famous

Montgolfier Brothers who made the first successful tests with a hot air balloon.

Normal mills need a continous water flow to power their water wheel. The

basic idea of the recirculation mill is the usage of a a closed water system.

Such machines sometimes are called dry water mills. Since the water

does not come from external sources, it was called aqua morta i.e.

"dead water". The intended advantage of this mill is clear. There is no need

for a permanent water flow, which in plains or dry periods can be crucial.

A general analysis of recirculation mills must focus on two aspects:

-

The total efficiency of the closed-loop system. We have seen already that

both pumps and water wheels can have up to 80% efficiency each. This would

result in a total efficiency of 64%, which is not sufficient to keep the

mechanism running. The mechanisms at Strada's or Boeckler's time hardly would

have reached more than a total degree of performance than 10%.

-

If the efficiency of the mechanical parts could be improved to the maximum

of 100%, we have to consider the fact, that a fixed amount of water is running

down and lifted again. We have learned already, that by this, no useful work

can be generated.

yyy

***image***

Leonardo's idea is far ahead of its time.

Jacopo Strada and Andreas

Böckler

***image***

This construction by Strada contains a nice detail, that ruins the whole

idea, even if it would work. Have a closer look at the water tap above the

grindstone. Although this is very convenient for the worker, it will continously

empty the water reservoir, thus decreasing the power of the machine. Here

the construction fails due to user-friendly engineering.

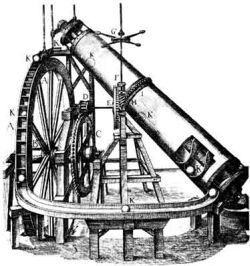

For completeness, Robert Fludd shall be mentioned here. His recirculation

mill is frequently depicted and often said to be the first recirculation

mill at all. After reading the previous chapters, you may also share my opinion

that Fludd refurbished an idea which was not at all new at his time.

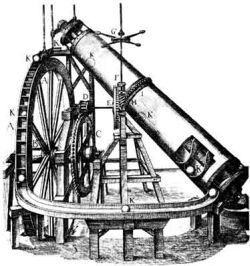

***image***

This particular design promises a bad efficiency due to the layout of the

central gearbox.

Rolling ball machines are a variant of recirculation mills. The idea on which

these machines are based is the same, but the medium is different. Instead

of using a liquid, rolling ball machines work on balls which are transported.

Although this detail changes a lot in the technology of the machine and the

behaviour of the transported medium, the analysis of rolling ball machines

can be done with the same basic methods. These rolling ball machines should

not be confused with rolling-ball clocks, in which the balls are used to

both entertain the viewer and to give a time normal instead of the use of

a pendulum.

|

|

Ulrich von Granach gave the description of a recirculation mill based

on the movement of heavy cannon balls instead of water. Although this use

of recycled war material for civil purposes must be appreciated, it did not

work.

This machine contains a very interesting detail. It is the gear labelled

with E, which is a worm gear with axles crossing at an angle

unequal to 90°. Worm gears were not very familiar at von Granach's time

and this particular element shows quite deep insight into kinematic principles.

However, even today this arrangement is avoided, as it imposes great difficulties

in manufacturing the parts and adjusting the gear. |

|

|

PMMs which are based on rolling balls easily can be debunked. As each

single ball runs on a closed path, the total energy win is zero. The shape

of the path has no influence onto the energy bilance. In this case, friction

is the correct explanation for the failure this type of machines. Friction

is not only found in the bearings of the wheels, but also in the work to

bend the conveyer belt or inner friction caused by banging of the balls into

their locations of the wheel's shovels. |